Products

B40 B60 B80 B100 95% Purity Zirconia Zro2 Ceramic Sand

Zirconium Oxide Description

Zirconium Oxide Sand, also known as ceramic sand, is made from zirconium dioxide, silicon dioxide and aluminium trioxide in a specific formulation and is fired at over 2250 degrees,particularly suitable for surface treatment work on complex workpieces of metal and plastic structure, improving the fatigue life of the workpiece surface and removing burrs and flying edges.

Zirconium Oxide Specifications

| ZrO2 | SiO2 | Al2O3 | Density | Stacking density | Hardness reference values | |

| 60-70% | 28-33% | <10% | 3.5 | 2.3 | 700 (HV) | 60HRC (HR) |

Zirconium Oxide Granularity

| Specification | Grain size (mm or um) |

| B20 | 0.600-0.850mm |

| B30 | 0.425-0.600mm |

| B40 | 0.250-0.425mm |

| B60 | 0.125-0.250mm |

| B80 | 0.100 - 0.200mm |

| B120 | 0.063-0.125mm |

| B170 | 0.040-0.110mm |

| B205 | 0.000 - 0.063mm |

| B400 | 0.000 - 0.030mm |

| B505 | 0.000 - 0.020mm |

| B600 | 25±3.0um |

| B700 | 20±2.5um |

| B800 | 14.5±2.5um |

| B1000 | 11.5±2.0um |

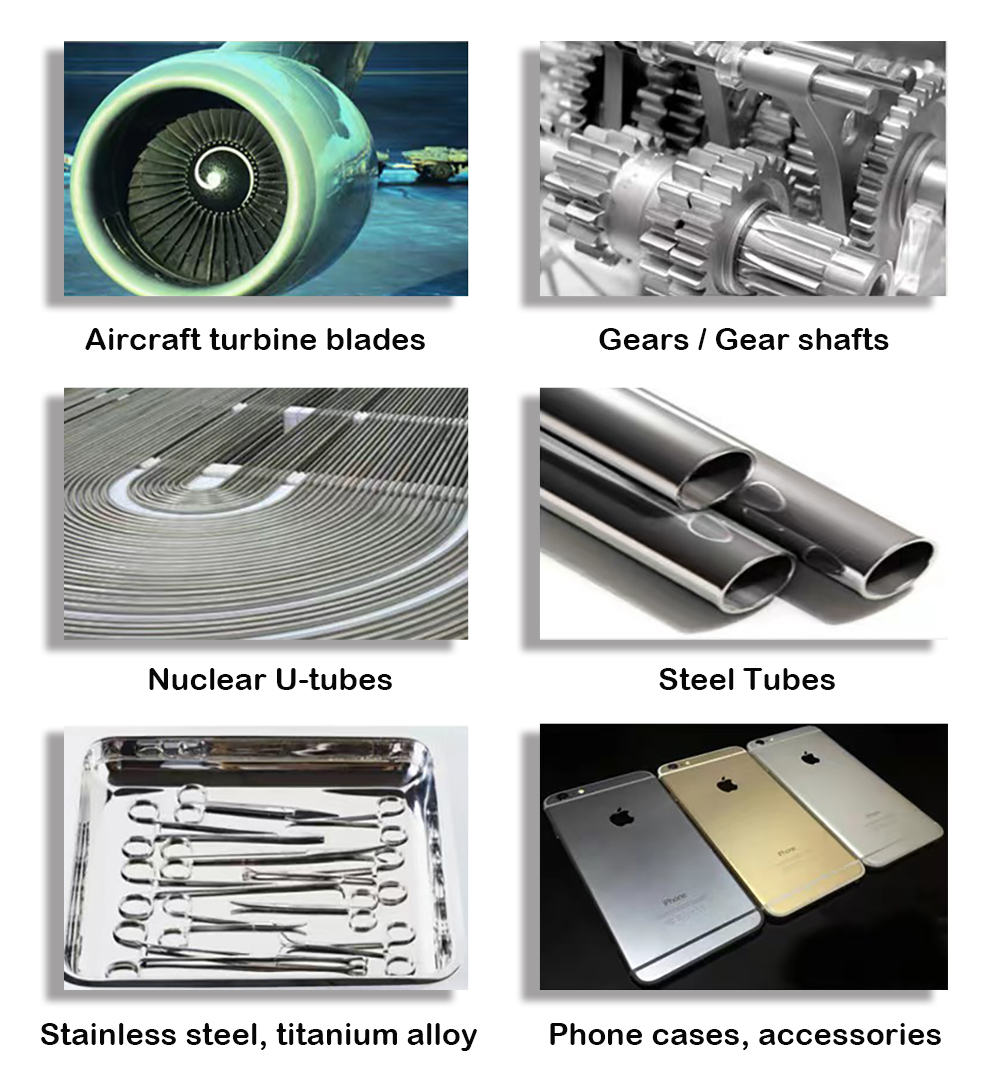

- Aerospace equipment: manufacture and repair of titanium alloy materials.

- Mould and die industry: cleaning and maintenance

- Metalwork: reinforcement, aesthetic effects

- Plastics, electronics industry: deburring of circuit boards, aesthetic effects

- Automotive industry: anti-fatigue and strengthening treatment of shock spring surfaces

- Turbine industry: surface fatigue treatment and strengthening of turbine blades

Your Inquiry

If you have any questions.Please feel free to contact us.

inquiry form

Write your message here and send it to us