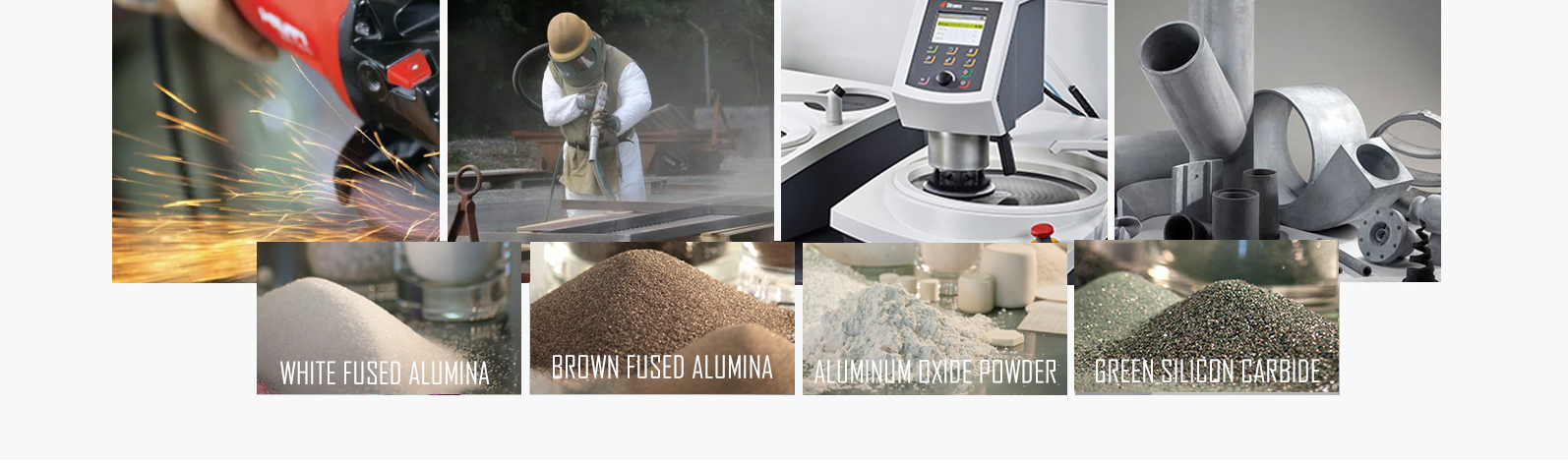

Products

F12-F220 White Fused Alumina Oxide Grits

White fused alumina

White fused alumina is made of high-purity low-sodium alumina powder by melting at the high temperature, cooling crystallization, and then crushing. The white fused alumina grit is under strict controlling to keep the grain size distribution and the consistent appearance.

Whiet Fused Alumina Properties

White, α crystal over 99%, high purity, high hardness, and high toughness, strong cutting force, strong chemical stability, and strong insulation.

|

Mohs hardness |

9 |

|

Bulk density |

1.75-1.95g/cm3 |

|

Specific gravity |

3.95g/cm3 |

|

Volume density |

3.6 |

|

Melting degree |

2250℃ |

|

Refractory degree |

2000℃ |

| Used for refractory, castable | |||||

|

Properties |

0-1 1-3 3-5m/m |

F100 F200 F325 |

|||

|

Guarantee Value |

Typical Value |

Guarantee Value |

Typical Value |

||

|

Chemical Composition |

Al2O3 |

≥99.1 |

99.5 |

≥98.5 |

99 |

|

SiO2 |

≤0.4 |

0.06 |

≤0.30 |

0.08 |

|

|

Fe2O3 |

≤0.2 |

0.04 |

≤0.20 |

0.1 |

|

|

Na2O |

≤0.4 |

0.3 |

≤0.40 |

0.35 |

|

| Used for abrasives,blasting,grinding | |||

|

Properties |

Grains |

||

|

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# |

|||

|

Guarantee Value |

Typical Value |

||

|

Chemical Composition |

Al2O3 |

≥99.1 |

99.5 |

|

SiO2 |

≤0.2 |

0.04 |

|

|

Fe2O3 |

≤0.2 |

0.03 |

|

|

Na2O |

≤0.30 |

0.2 |

|

| Used for abrasives ,lapping,Polishing | ||||

|

Properties |

Micropowder |

|||

|

"W" |

W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 |

|||

|

"FEPA" |

F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 |

|||

|

"JIS" |

240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# 10000# 12500# |

|||

|

Guarantee Value |

Typical Value |

|||

|

Chemical Composition |

Al2O3 |

≥99.1 |

99.3 |

|

|

SiO2 |

≤0.4 |

0.08 |

||

|

Fe2O3 |

≤0.2 |

0.03 |

||

|

Na2O |

≤0.4 |

0.25 |

||

1.Sandblasting, polishing and grinding of metal and glass.

2.Filling of the paint, wear-resistant coating, ceramic, and glaze.

3.Making of oil stone, grinding stone, grinding wheel, sandpaper and emery cloth.

4.Production of ceramic filter membranes, ceramic tubes, ceramic plates.

5.Production of polishing liquid, solid wax and liquid wax.

6.For the use of wear-resistant floor.

7.Advanced grinding and polishing of piezoelectric crystals, semiconductors, stainless steel, aluminum and other metals and non-metals.

8.Specifications and composition

Your Inquiry

If you have any questions.Please feel free to contact us.