Products

Metal abrasive Steel Grit Blast Media

STEEL GRIT

This aggressive media is used in blasting and stripping steel and foundry metals. Steel Grit effectively produces an etching on hard metals for better adhesion of coatings including paints, epoxy, enamel and rubber. Uses include rail car reconditioning, removal of flashing, blasting bridges, metal parts and forging industry applications.

|

Products

|

Steel Grit

|

|

|

Chemical Composition |

CR

|

1.0-1.5%

|

|

C

|

1.0-1.5%

|

|

|

Si

|

0.4-1.2%

|

|

|

Mn

|

0.6-1.2%

|

|

|

S

|

≤0.05%

|

|

|

P

|

≤0.05%

|

|

|

Hardness

|

Steel shot

|

GP 41-50HRC;GL 50-55HRC;GH 63-68HRC

|

|

Density

|

Steel shot

|

7.6g/cm3

|

|

Micro structure

|

Martensite structure

|

|

|

Appearance

|

Spherical Hollow particles<5% Crack particle<3%

|

|

|

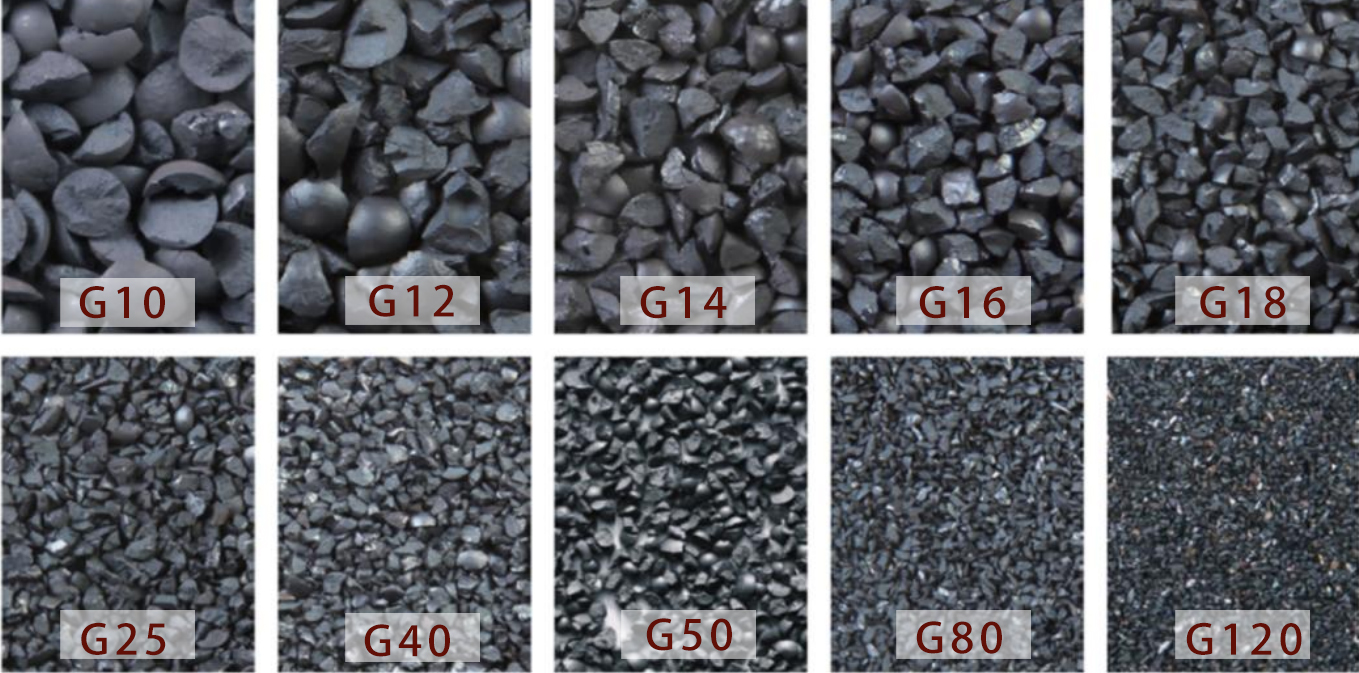

Type

|

G120,G80,G50,G40,G25,G18,G16,G14,G12,G10

|

|

|

Diameter

|

0.2mm,0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm

|

|

Steel Grit Application

1.Surface Preparation: Steel grits are widely used for surface preparation before applying coatings, paints, or adhesives. They effectively remove rust, scale, old coatings, and contaminants from metal surfaces, ensuring proper adhesion of the subsequent materials.

2.Rust and Corrosion Removal: Steel grits are used to remove heavy rust, corrosion, and mill scale from metal surfaces, especially in industries such as shipbuilding, marine maintenance, and structural steel fabrication.

3.Preparation for Welding: Prior to welding or other joining processes, steel grits can be used to clean and prepare surfaces, ensuring strong and clean weld joints.

4.Concrete and Stone Surface Preparation: Steel grits can be used to clean and prepare concrete and stone surfaces, such as for restoration projects, where the removal of old coatings, stains, or contaminants is necessary.

5.Shot Peening: While steel shots are more commonly used for shot peening, steel grits can also be utilized for this process. Shot peening involves bombarding a surface with abrasive particles to induce compressive stress, which enhances the material’s strength and fatigue resistance.

6.Deburring and Deflashing: Steel grits are used to remove burrs, sharp edges, and excess material from metal parts, especially in manufacturing processes where precision and smoothness are required.

7.Foundry Applications: Steel grits are used in foundries for cleaning and preparing casting surfaces, mold and core removal, and general metal surface treatment. 8.Surface Profiling: Steel grits are employed to create specific surface profiles, especially in industries like construction and shipbuilding. These profiles improve coating adhesion and provide better grip for anti-slip surfaces.

9.Stone Cutting and Etching: In the construction and monument industries, steel grits are used for cutting and etching stones and other hard materials, creating intricate designs and patterns.

10.Oil and Gas Industry: Steel grits are utilized for surface preparation in the oil and gas industry, such as cleaning pipelines, tanks, and other equipment.

11.Automotive Industry: Steel grits can be used for stripping paint and coatings from automotive parts, preparing surfaces for refinishing or restoration.

It’s important to note that the selection of the appropriate steel grit size, hardness, and other specifications depends on the specific application and the desired surface finish. The abrasive properties of steel grits make them valuable tools for tasks requiring robust material removal and surface modification.

Your Inquiry

If you have any questions.Please feel free to contact us.