Application of brown corundum micro powder in the field of abrasives

With the rapid development of modern industrial technology, abrasives, as an indispensable part of industrial production, has an increasingly wide range of applications. As an important part of abrasives, brown corundum micro powder, with its unique physical and chemical properties, plays an important role in grinding, polishing, lapping and other processes. This paper will introduce in detail the application of brown corundum micro powder in the field of abrasives, as well as its unique advantages and future development prospects.

I. Basic properties of brown corundum micro powder

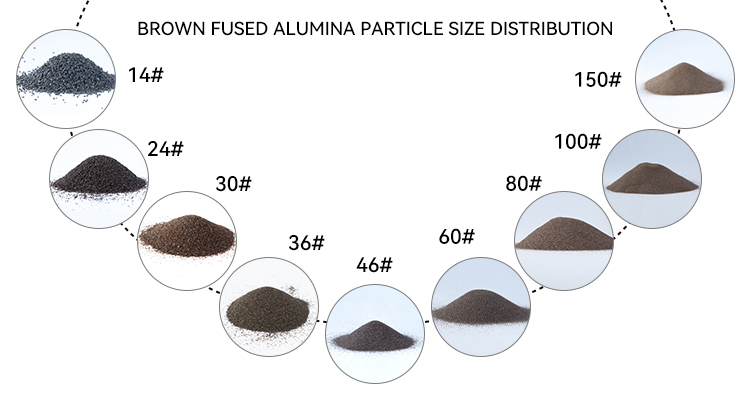

Brown corundum micro powder is a kind of micro powder product made of brown corundum as raw material, after crushing, grinding, grading and other processes. Brown corundum is a kind of oxide mineral with high hardness, high toughness and high wear resistance, so the micro powder made of brown corundum also has these characteristics. Brown corundum micropowders are available in a wide range of particle sizes, from a few microns to several hundred microns, and can be customised according to different process requirements. In addition, brown corundum micro powder also has the advantages of good chemical stability, corrosion resistance, good thermal conductivity and so on.

Application of brown corundum micro powder in the field of abrasives

In the processing of metal, non-metal and other materials, it is often necessary to use the grinding process to achieve the required surface accuracy and finish. Brown corundum micropowder is an ideal choice for the grinding process because of its high hardness and good wear resistance. Adding the right amount of brown corundum powder to the grinding tool can significantly improve the grinding efficiency and quality of the grinding tool, and extend the service life of the grinding tool.

Polishing is an important process to improve the surface finish of workpiece. Brown corundum powder has a wide range of applications in the polishing process. Because of its particle shape is more regular, and high hardness, wear resistance is good, so it can effectively remove the tiny bumps on the surface of the workpiece, so that the surface of the workpiece is smoother. In addition, brown corundum powder can also be used with other polishing materials to further improve the polishing effect.

Grinding refers to the action of abrasive, so that the surface of the workpiece to achieve a certain degree of finish and precision. Brown corundum micro powder also has an important application in the grinding process. Due to its wide range of particle size, it can be selected according to different grinding needs. At the same time, the chemical stability of brown corundum powder is good, will not cause corrosion on the workpiece, to ensure the grinding quality and the surface quality of the workpiece.

Advantages of brown corundum powder in abrasives field

1. high hardness and wear resistance: brown corundum powder has high hardness and wear resistance, which can effectively improve the grinding efficiency and service life of grinding tools.

2. good chemical stability: brown corundum powder has good chemical stability, will not cause corrosion to the workpiece, to ensure the grinding quality and the surface quality of the workpiece.

3. Wide range of grain size: brown corundum micro powder has a wide range of grain size, which can be customised according to different process requirements to meet the needs of various abrasives.

4. Wide range of applications: brown corundum micro powder is not only used in grinding, polishing, lapping and other processes, but also in other fields, such as coatings, rubber, plastics and other industries.