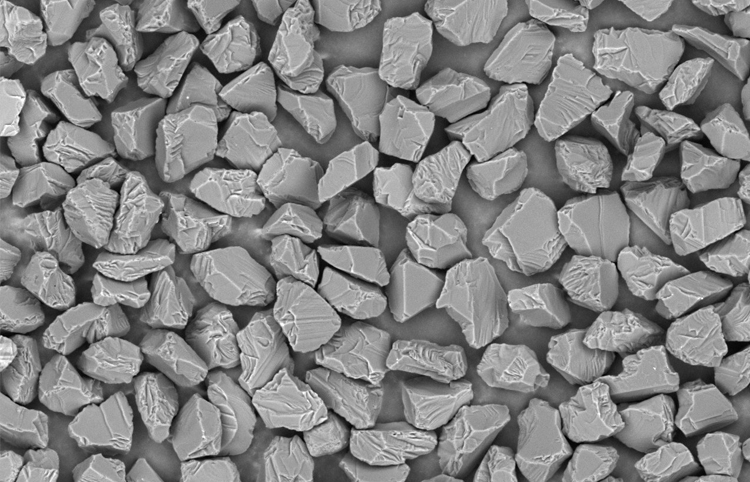

As the demand for diamond micropowder continues to rise, its applications in various industries have expanded significantly. From abrasives to cutting tools, and from electronics to medicine, diamond micropowder plays a critical role in many high-tech sectors. However, to meet the growing quality demands, one of the crucial steps in its production process is particle size classification.

After undergoing ball milling, crushing, shaping, and coarse purification, diamond micropowder still requires one vital processing step—particle size classification. The goal of this stage is to ensure a uniform particle size distribution while completely eliminating oversized particles.

Due to the fine nature of diamond micropowder, traditional sieve-based methods cannot achieve the precision required. Therefore, adopting scientific, efficient, and precise classification techniques is especially important. With the expanding applications of diamond micropowder and increasing quality demands from the market, manufacturers commonly use several classification methods. These include natural settling, centrifugal classification, overflow classification, and hydrocyclone classification.

Natural Settling Classification

The natural settling method is based on the principle that, under the same specific gravity, particles of different sizes settle at different rates in a liquid. In this method, particles are classified by controlling the settling height and time.

When a particle moves through a fluid, it is influenced by three forces: the particle’s own gravitational force, the buoyancy of the liquid, and the resistance exerted by the medium. The settling velocity of a particle depends on factors such as the contact area between the particle and the medium, the viscosity of the fluid, and the frictional resistance experienced by the particle.

Centrifugal Classification

Centrifugal classification operates on the same principle as natural settling but uses centrifugal force generated by a centrifuge to separate the micropowder. For coarser particles, their greater mass allows them to settle faster, and natural settling can effectively separate particles of similar size. However, for finer particles, the slow settling speed under gravity significantly extends the production cycle, occupying substantial space and containers. Ultra-fine particles may even fail to separate effectively due to Brownian motion and particle interference.

By contrast, centrifugal force accelerates the movement of microparticles, speeding up the classification process. This makes centrifugal classification highly efficient for fine particles, significantly improving production efficiency and product quality. Therefore, many manufacturers combine natural settling and centrifugal classification for a full range of fine-to-coarse powders. This hybrid approach optimizes both production efficiency and product quality.

Overflow Classification

Overflow classification can be understood as a reverse settling method. In an overflow classifier, water is introduced at the bottom of a conical container. As the water flows upwards, its speed gradually decreases and stabilizes in the cylindrical section at the top.

Diamond particles move against the rising water flow, and when the forces of gravity and the opposing upward force balance, particles of a certain size will remain suspended in the water. Finer particles will overflow from the container, while coarser particles will settle in the conical section. By adjusting the flow rate, manufacturers can obtain products of specific particle sizes.

While overflow classification is relatively slow and consumes large amounts of water, it offers high precision and requires fewer manual labor resources compared to other methods. The key factors influencing the efficiency of this technique are particle shape and flow rate control. Irregular particle shapes can cause inconsistent movement within the fluid, disrupting the classification process. Additionally, unstable flow control can lead to mixing of coarse and fine particles, preventing accurate separation.

Hydrocyclone Classification

Hydrocyclone classification uses centrifugal settling principles to separate particles by accelerating the separation process through high-speed rotation within a hydrocyclone. This technique is widely used for coarse classification and product dehydration. Its main advantages include speed, simplicity, good repeatability, and continuous feeding. It works effectively for all diamond micropowders except for those finer than 2 microns. However, it is less precise than other methods.

Choosing the Right Classification Method

Each classification method has its inherent advantages and drawbacks. In actual production, manufacturers can select the most suitable method based on their specific requirements. Some may opt for a single classification method, while others may combine multiple techniques to achieve optimal results. By carefully selecting and combining classification methods, companies can ensure that their diamond micropowder products meet the highest quality standards.

As the market for diamond micropowder continues to evolve, the development of advanced classification technologies will be essential in meeting the growing demand for more precise and efficient products across a wide range of industries.