How to choose the right white corundum grain size?

In industrial production, white corundum particle size selection is a crucial process parameter. The right grain size not only affects the appearance and quality of the product, but also relates to production efficiency and cost. In this article, we will discuss the selection method of white corundum particle size, to help readers understand how to select the most suitable particle size according to the actual needs, to enhance the production efficiency.

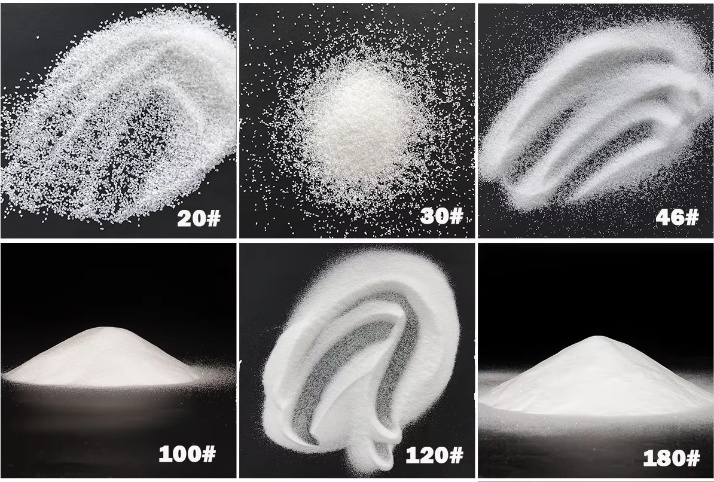

Ⅰ、Classification and characteristics of white corundum particle size

1. Coarse grain size: suitable for rough processing and heavy load operation. The advantage is high production efficiency. The disadvantage is that the grinding point is relatively concentrated, which is easy to cause thermal damage to the workpiece.

2. Medium grain size: Suitable for medium load processing, the advantage is that the grinding point is relatively dispersed, thermal damage is small, the disadvantage is that the productivity is relatively low.

3. Fine grain size: Suitable for precision machining, mirror effect, etc. The advantages are uniform distribution of grinding points, low thermal damage, and low productivity. The advantage is that the grinding point is evenly distributed, good surface quality, the disadvantage is that the processing is difficult, high requirements for equipment.

Ⅱ、How to choose suitable white corundum particle size?

1. Choose the suitable particle size according to the processing object: according to the material, hardness, roughness and other factors of the processing object, choose the suitable white corundum particle size. Generally speaking, the processing of soft materials should choose fine particle size to improve the surface finish; when processing hard materials, medium or coarse particle size can be chosen to improve the cutting force.

2. Consider the production efficiency and cost: When choosing the particle size, the production efficiency and cost should be considered. Too large a grit size may lead to longer production cycles and increased costs; while too small a grit size may result in waste of resources and increased abrasive consumption. Therefore, it is crucial to choose the right grain size according to the actual demand.

3. Reference to industry standards and experience: Different industries and different equipment have different needs for white corundum grain size. When selecting the grain size, you can refer to the industry standards and the experience of senior practitioners to ensure that the selected grain size meets the actual production needs.

4. Test cut verification: To ensure the accuracy of the selected particle size, it is recommended to conduct a test cut verification. Through the test cut, you can intuitively understand the impact of different particle size on product appearance, quality and production efficiency, so as to provide a strong basis for subsequent production.