Products

Synthetic Diamond Polishing Micro Powder

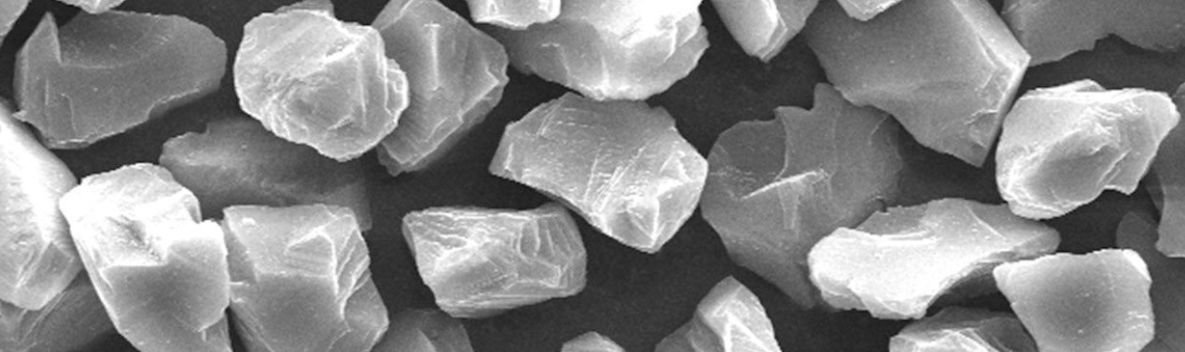

Monocrystalline Diamond Powder

Monocrystalline Diamond Powder is produced from artificial diamond single crystal abrasive grains by static pressure method, which are crushed and shaped using a special process for super-hard materials. Its particles retain the single crystal properties of single crystal diamond.

|

Specification |

D50 (μm)

|

Specification

|

D50 (μm)

|

|

0-0.05

|

0.05

|

5-10

|

6.5

|

|

0-0.08

|

0.08

|

6-12

|

8.5

|

|

0-0.1

|

0.1

|

8-12

|

10

|

|

0-0.25

|

0.2

|

8-16

|

12

|

|

0-0.5

|

0.3

|

10-20

|

15

|

|

0-1

|

0.5

|

15-25

|

18

|

|

0.5-1.5

|

0.8

|

20-30

|

22

|

|

0-2

|

1

|

20-40

|

26

|

|

1-2

|

1.4

|

30-40

|

30

|

|

1-3

|

1.8

|

40-60

|

40

|

|

2-4

|

2.5

|

50-70

|

50

|

|

3-6

|

3.5

|

60-80

|

60

|

|

4-8

|

5

|

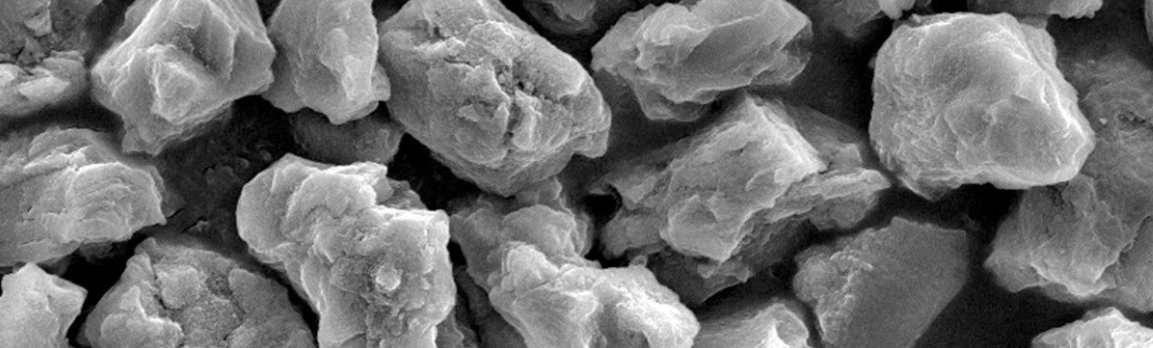

Polycrystalline Diamond Powder

Polycrystalline diamond powder is micron and sub-micron polycrystalline particles composed of diamond grains with a diameter of 5~10nm bonded through unsaturated bonds. The interior is isotropic and has no cleavage planes. Has high toughness. Due to its unique structural properties, it is often used for grinding and polishing semiconductor materials, precision ceramics, etc.

Available sizes of diamond micro powder are as below:

Product Characteristics

-Oversize completely removed

-Narrow PSD

-Surface purity can reach ppm level

-Outstanding dispersibility

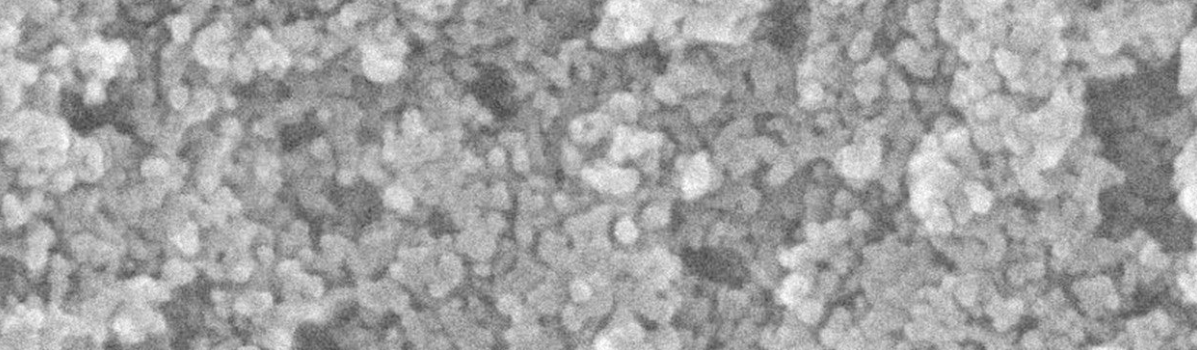

Nano Diamond Powder

Nano diamond powder is formed with tiny crystals below 20 nanometer, the special detonative condition produces sphere shaped diamond with rich functional group on the surface,its specific surface area is increased by one order of magnitude contrasted with the monocrystalline diamond. This product not only has the excellent hardness and grinding characteristics of diamond, but also has the new characteristics of nanofunctional materials.

|

Sizes

|

ND50

|

ND80

|

ND100

|

ND120

|

ND150

|

ND200

|

ND300

|

ND500

|

ND800

|

|

D50(nm)

|

45-55

|

75-85

|

90-110

|

110-130

|

140-160

|

180-220

|

280-320

|

450-550

|

750-850

|

Characteristics

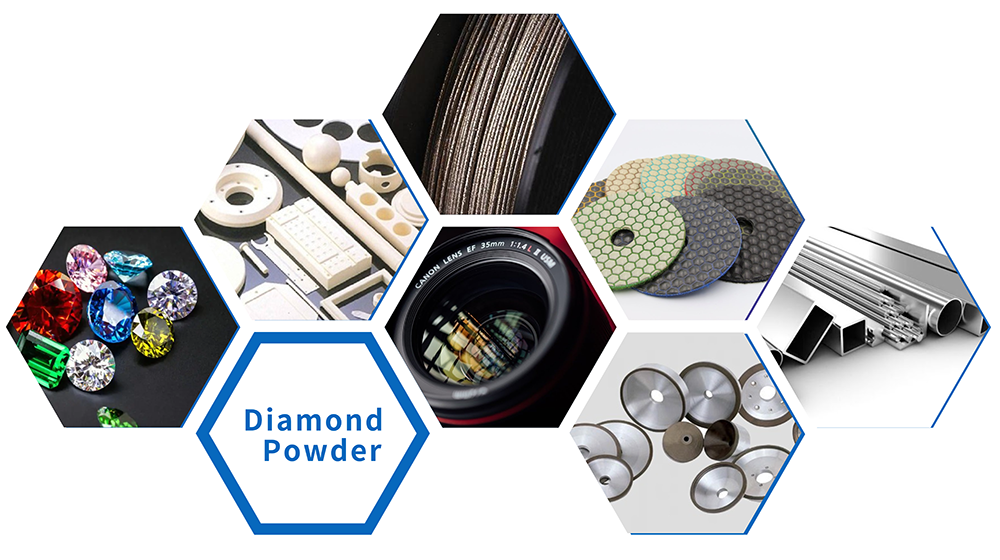

Monocrystalline Diamond Powder Application

1. Suitable for various high-precision electroplated diamond wires, electroplated diamond grinding wheels, SiC crystal cutting, knives, ultra-thin saw blades, etc.

2. Suitable for diamond composite sheets, diamond polycrystalline and metal bond products, ceramic bond products, electroplated diamond products, etc.

3. Suitable for electroplated diamond tools, grinding wheels, etc. specially used for processing hard and brittle materials.

4. Suitable for precision grinding and polishing of high-end precision gems, lenses, metallographic consumables, LCD panels, LCD glass, sapphire, quartz sheets, LED sapphire substrates, LCD glass, ceramic materials, etc.

Polycrystalline Diamond Powder Applications

1.Thin and polishing of semiconductor wafers, such as SiC wafer and sapphire

2.Surface polishing of various ceramic materials

3.Surface polishing of metal materials ,such as stainless steel, aluminum alloy and so on

Nano Diamond Powder Applications

1. Super fine polishing. The surface roughness of polished workpieces could reach angstrom-level without scratches, which can satisfy the most rigorous polishing applications demand.

2. Nano diamond can be used as lubricating oil additives. The sliding friction will be changed into rolling friction,which can reduce the friction coefficient and significantly improve the friction performance and also prolong the service life.

3. Composite plating and spraying on the surface of various workpieces,enhance wear resistance, corrosion resistance, impact toughness and hardness of the workpieces’ surface.

4. As rubber and plastics additives, nano diamond can significantly enhance its wear resistance, puncture resistance, tensile property and also slow down the ageing process.

5. High purity nano diamond will not cause biological rejection, meanwhile it can be widely used in medical, biological and cosmetic fields because of its big specific surface area, strong adsorption potential.

Your Inquiry

If you have any questions.Please feel free to contact us.