Products

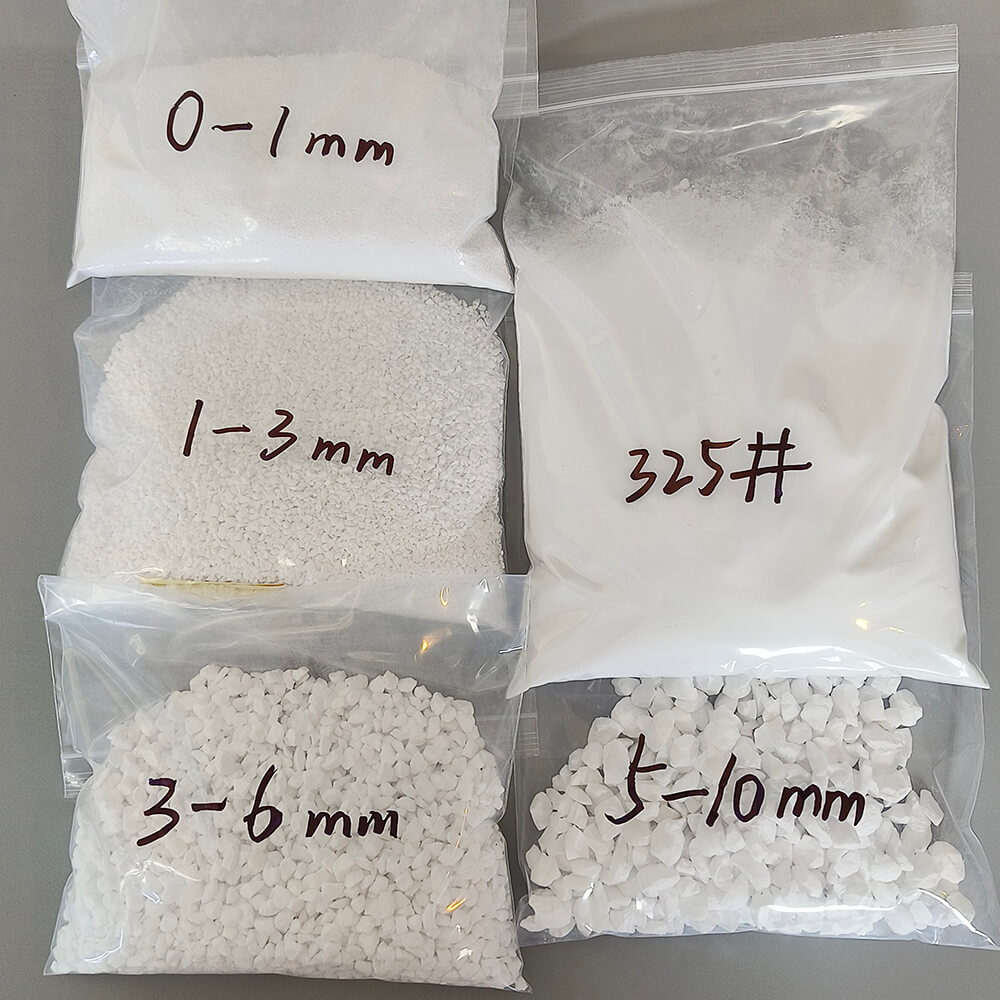

Tabular Alumina for Refractory Dry Ramming Mass Sintered Tabular Alumina for Refractory Raw Materials

Sintered Tabular Alumina Description

Tabular corundum, also known as sintered tabular alumina, is a high-purity form of alumina (Al2O3) that is specifically processed to have a unique tabular, or flat, shape. It is produced by sintering (heating without melting) high-grade alumina powder at temperatures above 1900°C, causing the alumina particles to grow and form large, flat, plate-like crystals.

Tabular Corundum Specification

| Tabular corundum Specification | ||

| Item | Standard | Test |

| Apparent Gravity | 3.5g/cm3 min | 3.56g/cm3 |

| Apparent Porosity | 5.0% max | 3.5% |

| Water Absorption | 1.5% max | 1.1% |

| Chemical Composition | ||

| Item | Standard % | Test % |

| Al2O3 | 99.2 min | 99.4% |

| Na2O | 0.40 max | 0.29% |

| Fe2O3 | 0.10 max | 0.02% |

| CaO | 0.10 max | 0.02% |

| SiO2 | 0.15 max | 0.03% |

| Usage: Tabular corundum is widely used in high-performance refractory materials in the fields of steel, casting, petrochemicals, breathable bricks, ladle linings, castables, prefabricated parts, ceramics and other fields. It is an excellent synthetic refractory raw material. Tabular corundum is used as Refractory aggregate can be used in combination with spinel, calcined activated alumina and binding agents such as cement, clay or resin. The prepared high-purity corundum bricks have low impurity content (such as SiO2), high bulk density and good thermodynamic properties, making corundum bricks Bricks are resistant to thermal, chemical and structural damage caused by the operation of gasifiers and other industrial furnaces. | ||

| Advantages: high refractoriness; high corrosion resistance; high erosion resistance; high thermal shock resistance; high strength, good toughness; stable chemical properties; resistance to alkaline slag erosion, good resistance to slag erosion, and good resistance to molten iron erosion ; Resistant to erosion by molten steel and good air permeability. | ||

Applications of tabular corundum

- Refractories

- Foundry and Investment Casting

- Ceramics Manufacturing

- Abrasives and Polishing

- Catalyst Supports

- Insulation Materials

- Electronics and Semiconductor Industry

Your Inquiry

If you have any questions.Please feel free to contact us.

inquiry form

Write your message here and send it to us