Products

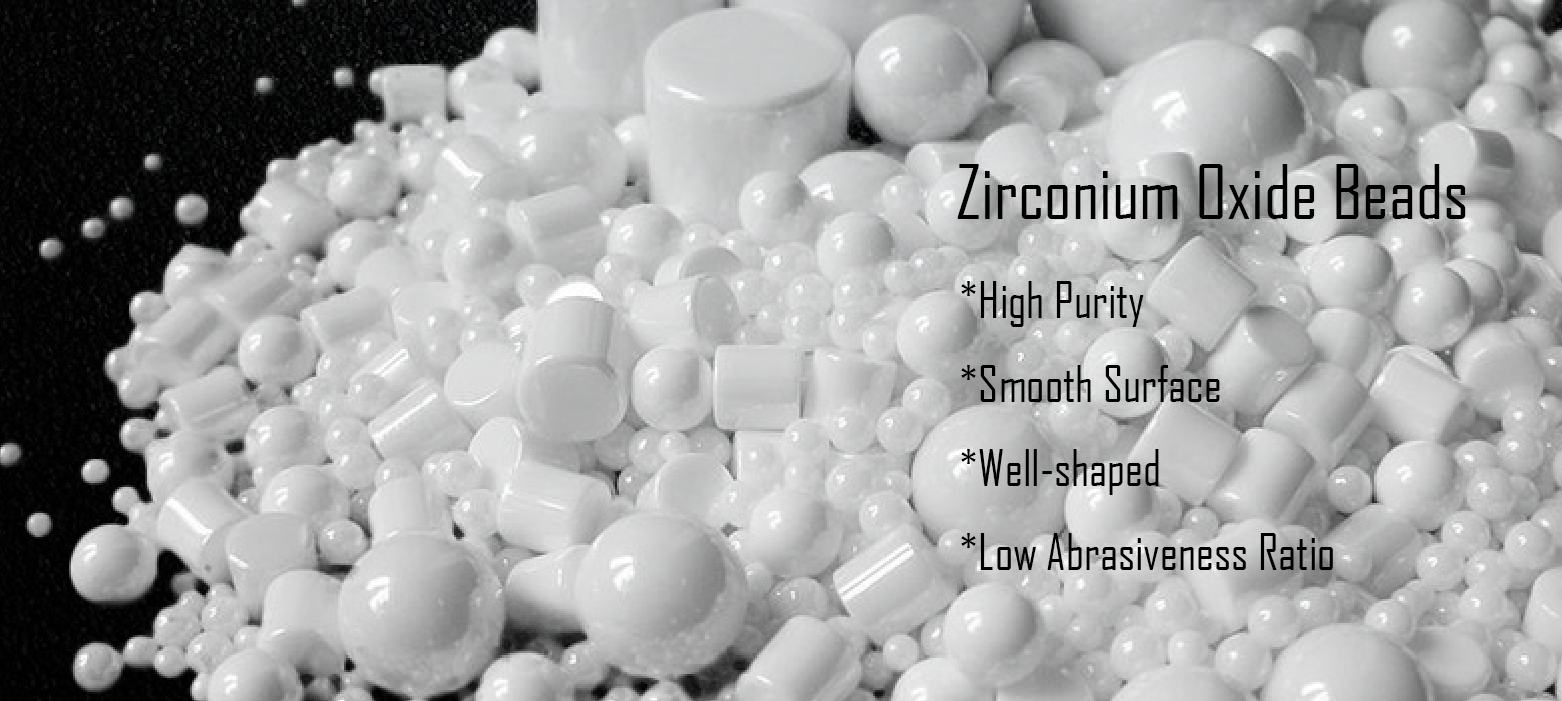

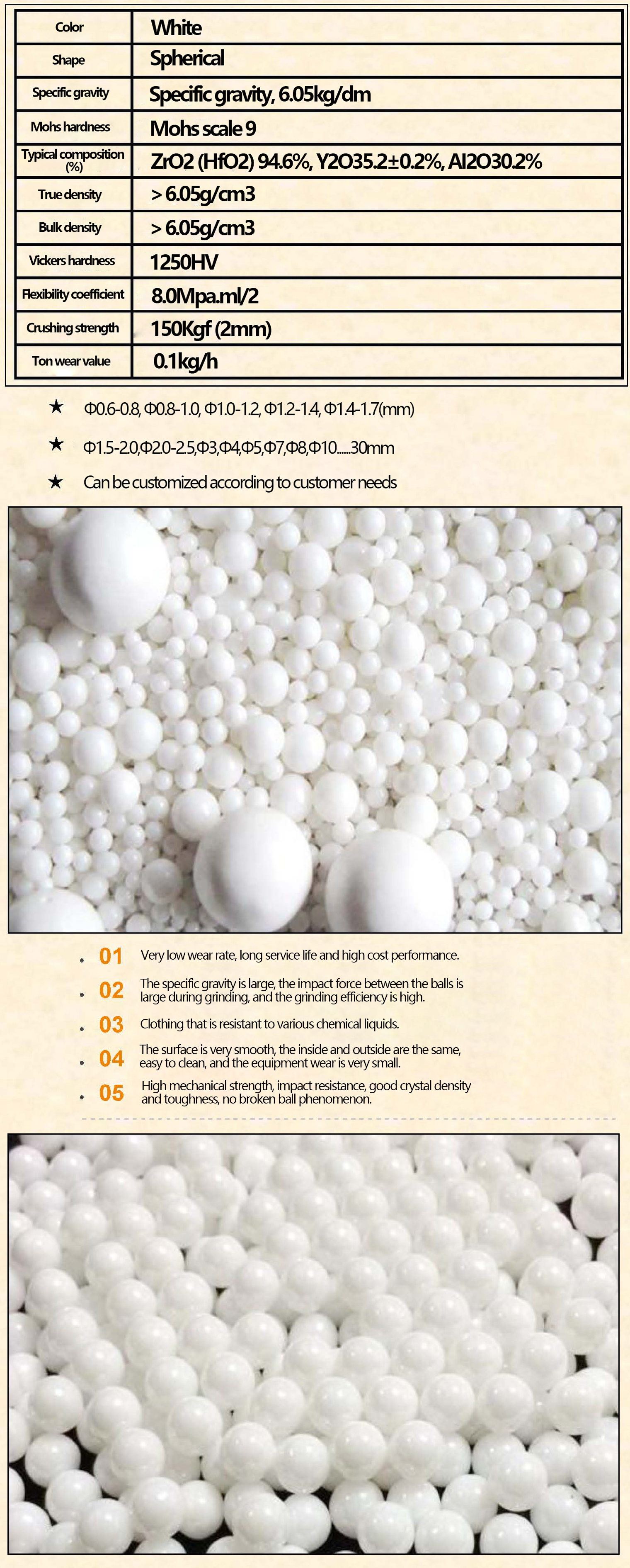

Yttria Stabilized Zirconia Porcelain Balls Zro2 Grinding Beads

Has a pearly luster and smooth working spherical surface. Using micron sub-nanoscale zirconiapowder as raw material, yttrium oxide or cerium oxide as stabilizer, titration or dry bag isostaticpressing into dry type, high temperature baking and phasing process, the shape is spherical, eachThe technical indicators and performance have reached the national advanced level, and it is thebest grinding medium. lt has extremely high strength and high toughness at room temperature.good wear resistance, high temperature resistance, corrosion resistance, high stiffness,non-maanetic conductivity, and electrical insulation, At 600 C. the strenath and hardness ofzirconia beads are almost unchanged, the density is 6g per cubic centimeter, and the thermaexpansion rate is close to the metal expansion rate, so it can be used in combination with metals.High specific gravity provides higher grinding efficiency; fine microstructure ensures better wearresistance: smooth working surface, perfect roundness, and a narrow particle size distribution ot+0.03mm reduces internal friction and setting of beads

Zirconia Beads Application

1.Bio-tech (DNA, RNA & protein extraction and isolation)

2.Chemicals including Agrochemicals e.g. fungicides, insecticides and herbicides

3.Coating, paints, printing and inkjet inks

4.Cosmetics (Lipsticks , Skin & sun protection creams)

5.Electronic materials and components e.g. CMP slurry, ceramic capacitors, lithium iron phosphate battery

6.Minerals e.g. TiO2, Calcium Carbonate and Zircon

7.Pharmaceuticals

8.Pigments and dyes

9.Flow distribution in process technology

10.Vibro-grinding and polishing of jewelrys, gemstones & aluminum wheels

11.Sintering bed with good thermal conductivity, can sustain high temperatures

Your Inquiry

If you have any questions.Please feel free to contact us.