Products

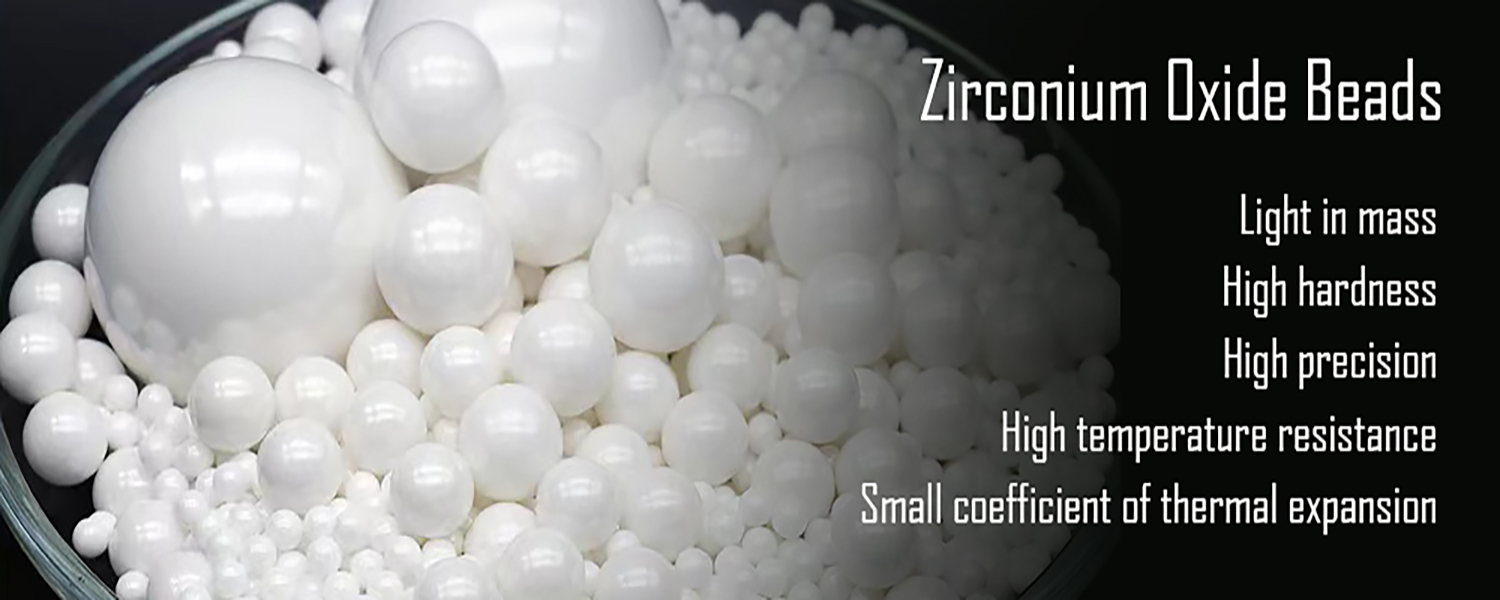

Zirconium Oxide Zirconia Ceramic Ball

Ceramic grinding material, abrasive media, deburring media, polishing consumables, high density ceramic polishing grains. We produce all kinds of mass polishing media material, ceramic media for fine polishing, porcelain polishing, light cutting, medium cutting, general cutting, fast cutting, very fast cutting and other types.

Chemical Composition

| Chemical Composition | ZrO2 | Y2O3 | Al2O3 | FeO3 | SiO2 | TiO2 | MgO | Na2O3 |

| % | 94.75 ±0.60 | 4.90±0.50 | 0.30±0.10 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

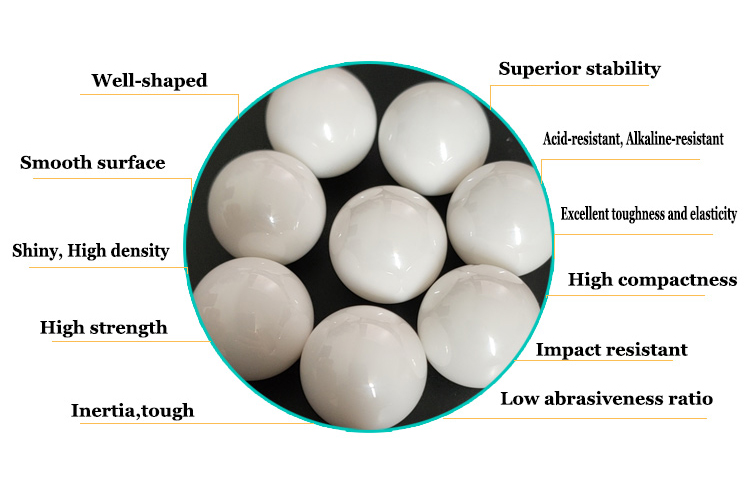

Physical Properties

| Density(g/cm³) | ≥6.05 |

| Bulk Density(g/cm³) | ≥3.6 |

| Hardness(Hv) | 1200 |

| Sphericity(%) | 95% |

Standard Size(mm):

| 0.1-0.2 | 0.2-0.3 | 0.3-0.4 | 0.4-0.6 | 0.6-0.8 | 0.8-1.0 | 1.0-1.2

|

1.2-1.4 |

| 1.4-1.6 | 1.6-1.8 | 1.8-2.0 | 2.0-2.2 | 2.2-2.4 | 2.4-2.6 | 2.6-2.8 | 2.8-3.2 |

| 3.0-3.5 | 3.5-4.0 | 4.0-4.5 | 4.5-5.0 | 5.0-5.5 | 5.5-6.0 | 6.0-6.5 | 6.5-7.0 |

| 8 | 10 | 15 | 20 | 25 | 30 | 50 |

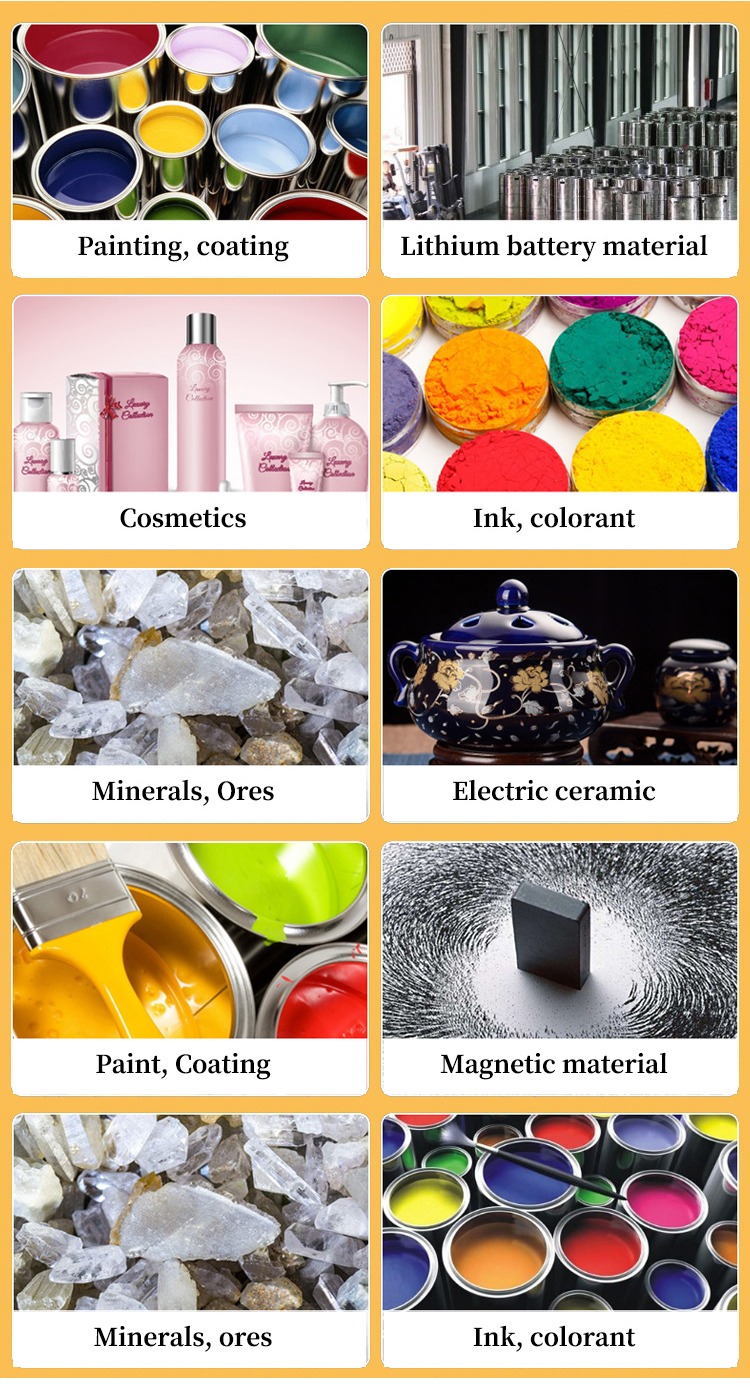

Zirconia Beads Application

1.Bio-tech (DNA, RNA & protein extraction and isolation)

2.Chemicals including Agrochemicals e.g. fungicides, insecticides and herbicides

3.Coating, paints, printing and inkjet inks

4.Cosmetics (Lipsticks , Skin & sun protection creams)

5.Electronic materials and components e.g. CMP slurry, ceramic capacitors, lithium iron phosphate battery

6.Minerals e.g. TiO2, Calcium Carbonate and Zircon

7.Pharmaceuticals

8.Pigments and dyes

9.Flow distribution in process technology

10.Vibro-grinding and polishing of jewelrys, gemstones & aluminum wheels

11.Sintering bed with good thermal conductivity, can sustain high temperatures

Your Inquiry

If you have any questions.Please feel free to contact us.