Products

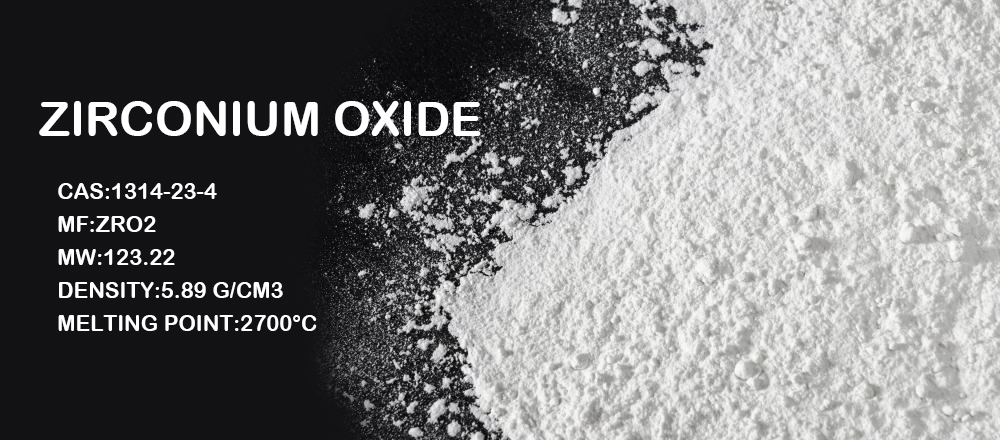

Zirconium oxide zirconia powder

Zircon Powder

Zirconia powder has the characteristics of high hardness, high-temperature resistance, chemical corrosion resistance, wear resistance, small thermal conductivity, strong thermal shock resistance, good chemical stability, outstanding composite material, etc. The properties of the material can be improved by combining nanometer zirconia with alumina and silicon oxide. Nano zirconia is not only used in structural ceramics and functional ceramics. Nano zirconia doped with different elements conductive properties, used in solid battery electrode manufacturing.

Physical properties

Very high melting point

Chemical stability at high temperatures

Low thermal expansion compared to metals

High mechanical resistance

Abrasion resistance

Corrosion resistance

Oxide ion conductivity (when stabilized)

Chemical inertia

Specifications

| Properties Type | Product types | ||||

| Chemical Composition | Normal ZrO2 | High purity ZrO2 | 3Y ZrO2 | 5Y ZrO2 | 8Y ZrO2 |

| ZrO2+HfO2 % | ≥99.5 | ≥99.9 | ≥94.0 | ≥90.6 | ≥86.0 |

| Y2O3 % | ----- | ------ | 5.25±0.25 | 8.8±0.25 | 13.5±0.25 |

| Al2O3 % | <0.01 | <0.005 | 0.25±0.02 | <0.01 | <0.01 |

| Fe2O3 % | <0.01 | <0.003 | <0.005 | <0.005 | <0.01 |

| SiO2 % | <0.03 | <0.005 | <0.02 | <0.02 | <0.02 |

| TiO2 % | <0.01 | <0.003 | <0.005 | <0.005 | <0.005 |

| Water Composition(wt%) | <0.5 | <0.5 | <1.0 | <1.0 | <1.0 |

| L.O.I(wt%) | <1.0 | <1.0 | <3.0 | <3.0 | <3.0 |

| D50(μm) | <5.0 | <0.5-5 | <3.0 | <1.0-5.0 | <1.0 |

| Surface area(m2/g) | <7 | 3-80 | 6-25 | 8-30 | 8-30 |

| Properties Type | Product types | ||||

| Chemical Composition | 12Y ZrO2 | Yello Y stabilized ZrO2 | Black Y stabilized ZrO2 | Nano ZrO2 | Thermal spray ZrO2 |

| ZrO2+HfO2 % | ≥79.5 | ≥94.0 | ≥94.0 | ≥94.2 | ≥90.6 |

| Y2O3 % | 20±0.25 | 5.25±0.25 | 5.25±0.25 | 5.25±0.25 | 8.8±0.25 |

| Al2O3 % | <0.01 | 0.25±0.02 | 0.25±0.02 | <0.01 | <0.01 |

| Fe2O3 % | <0.005 | <0.005 | <0.005 | <0.005 | <0.005 |

| SiO2 % | <0.02 | <0.02 | <0.02 | <0.02 | <0.02 |

| TiO2 % | <0.005 | <0.005 | <0.005 | <0.005 | <0.005 |

| Water Composition(wt%) | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| L.O.I(wt%) | <3.0 | <3.0 | <3.0 | <3.0 | <3.0 |

| D50(μm) | <1.0-5.0 | <1.0 | <1.0-1.5 | <1.0-1.5 | <120 |

| Surface area(m2/g) | 8-15 | 6-12 | 6-15 | 8-15 | 0-30 |

| Properties Type | Product types | |||

| Chemical Composition | Cerium stabilized ZrO2 | Magnesium stabilized ZrO2 | Calcium stabilized ZrO2 | Zircon aluminum composite powder |

| ZrO2+HfO2 % | 87.0±1.0 | 94.8±1.0 | 84.5±0.5 | ≥14.2±0.5 |

| CaO | ----- | ------ | 10.0±0.5 | ----- |

| MgO | ----- | 5.0±1.0 | ------ | ----- |

| CeO2 | 13.0±1.0 | ------ | ------ | ------ |

| Y2O3 % | ----- | ------ | ------ | 0.8±0.1 |

| Al2O3 % | <0.01 | <0.01 | <0.01 | 85.0±1.0 |

| Fe2O3 % | <0.002 | <0.002 | <0.002 | <0.005 |

| SiO2 % | <0.015 | <0.015 | <0.015 | <0.02 |

| TiO2 % | <0.005 | <0.005 | <0.005 | <0.005 |

| Water Composition(wt%) | <1.0 | <1.0 | <1.0 | <1.5 |

| L.O.I(wt%) | <3.0 | <3.0 | <3.0 | <3.0 |

| D50(μm) | <1.0 | <1.0 | <1.0 | <1.5 |

| Surface area(m2/g) | 3-30 | 6-10 | 6-10 | 5-15 |

Zirconia Powder Applications

Used as positive material:

For structural members:

For porcelain teeth:

Used to make back panel of mobile phone:

Used to make zirconia gem:

The production of zirconia gemstones from zirconia powder is an important field of zirconia’s deep processing and application. The synthetic cubic zirconia is a hard, colorless, and optically flawless crystal. Because of its low cost, durable, and similar appearance to diamonds, cubic zirconia gemstones have been the most important substitutes for diamonds since 1976.

Your Inquiry

If you have any questions.Please feel free to contact us.